test for torsion of tubing|metal torsion testing : exporting A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which . Resultado da A X Capital Bank, uma empresa de Florianópolis suspeita de operar uma .

{plog:ftitle_list}

21 de mai. de 2021 · Boa noite galera, estou em São Paulo a passeio, na carência procurei uma perva que realmente fosse daquelas tops que só encontraria aqui! Diante de um leque.

Introduction ........... 1. Torsion Fundamentals......... 3. 2.1 Shear Center.......... 3. 2.2 Resistance of a Cross-Section to. a Torsional .A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which .Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and. turbines) or stationary (such as with a bolt or . Torsion testing is appropriate for materials that may experience a torsional load like a metallic bone screw, an intramedullary rod, rubber tubing that may become twisted, or to .

One particularly valuable standard in axial-torsion testing is ASTM E2207. This standardized test method focuses on strain-controlled axial-torsional fatigue testing using thin .Torsion testing is a form of mechanical evaluation that assesses materials or devices while under angular displacement-induced stress. This method can be categorized into two distinct .

Torsion testing is a mechanical testing method used to determine the mechanical properties of materials under torsional or twisting forces. It involves applying torque to a .2.3 Avoiding and Minimizing Torsion The commonly used structural shapes offer relatively poor resistance to torsion. Hence, it is best to avoid torsion by detailing the loads and reactions to act through the shear center of the member. However, in some instances, this may not always be possible. AISC (1994) offers several sugges-The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion. Torsion, in its simplest form, is the action of twisting. . syringe components, wire, tubing, and many more. In the .

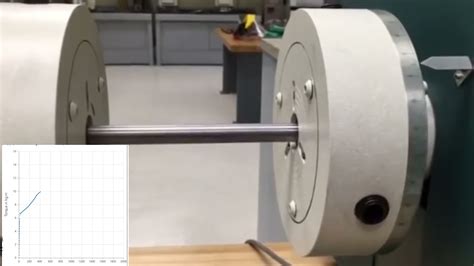

Square tubing that can perfectly fit onto composite shaft may ease the sample preparation in terms of horizontal alignment. Download : Download full-size image; Fig. 2. (a) Dimensions of torsion test specimen and steel tubing, (b) side view of torsion test specimen, (c) torsion test set-up. Download : Download full-size image; Fig. 3.Several axial-torsion test examples are measuring the adhesive properties of biopolymers; determining the mechanical properties of bone screws according to ASTM F543; or determining the durability of thin walled tubing. Many axial-torsion tests are quite demanding because the amplitudes and frequencies of each axis may vary greatly.

test specimen and calculating the slope of the shear stress versus shear strain curve. In addition, the torsion test specimen will be twisted to failure in order to determine the shear stress at the limit of proportionality. The shear stress at the limit of proportionality is the largest value of them) or foot-pound force (ftNatural frequency test of composite tube . International Conference on Technology (IConTech), November 16-19, 2023, Antalya/Turkey 199 Universal joint, tube yoke and yoke shaft were chosen steel materials depending on various reasons. Tube yoke . Static Torsion Test 3500 1

Torsion testing is a form of mechanical evaluation that assesses materials or devices while under angular displacement-induced stress. . Evaluating materials like metal wires or plastic tubing to determine properties such as shear strength and . Applying solely torsional loads to the test specimen. Axial-Torsion: Applying both axial . where X and Y are the principal planes, P is the axial load, and M X, M Y are the bending moments. The principal moments of inertia are I X and I Y.The fourth term in the foregoing equation gives the contribution to the normal stress due to the restraint of warping which results in the development of a bimoment M Ω. The quantities \(\omega .Brittle metal tube. Evaluation of fractures occurring during simple torsion test: (Source : Annex c, IS 1717:2012- Method of simple torsion testing of wire, Third Revision,2012) RELEVANT INDIAN STANDARD FOR TORSION TEST: IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test, Third Revision, 2012;

https://engineers.academy/A torsion test demonstration on two samples of material, grey cast iron and 0.4% carbon steel. In this torsion test we are able to . Torsion testing of basic grade mild steel with an axial torsional testing equipment is one type of test used to assess the torsional characteristics of the structural material.However, the torsion test also permits the shear but much larger deformation than in the simple shear test. The mode of deformation in torsion is easy to describe with precision, and it is easy to study the behaviour of the material in the plastic domain. Typically, the thin-walled tubular or solid cylindrical specimen is placed in a torsion .Important Note : In the notes and tables below J is used throughout for the torsion constant for circular and non circular sections. . This is the convention in structural design In structural design the use of sections i.e I sections, channel section, angle sections etc. should be avoided for applications designed to withstand torsional .

Ovarian torsion usually occurs on just one side and can cause sudden, intense pain and vomiting. It can also cause an infection (peritonitis) in the abdominal cavity. The majority of ovarian torsion cases affect women of reproductive .

welded open shapes, where normalized test data is even lower than that for A500 HSS. The apparent unconservative design of cold-formed HSS columns is not as critical as it appears. Much of the CIDECT test data was normalized by the offset yield of the section obtained from stub column tests. This reflects the inherentA torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. . Testing raw materials like metal wires or plastic tubing to determine properties such as shear strength and modulus, or; Functional testing of finished products subjected to torsion, such as screws .

MECHANICAL TUBING STEEL TUBE INSTITUTE OF NORTH AMERICA 2000 Ponce de Leon, Suite 600, Coral Gables, FL 33134 • Tel: (305) 421-6326 . resistance to torsion, and maximum strength to weight ratio are required. . between suppliers and users of welded tubing. The data shown for properties, test procedures, tolerances, sizes and other . The preparation of carbon fiber shaft winding process, static torsion test and fatigue test of prototype trial, and compared with the theoretical calculation results. . failure and other phenomena, to meet the requirements. At the same time, the axial tube in the static torsion up to 2600 N m fatigue test is still in good condition, The .7.2 Tube test pieces. 8 Accuracy of the testing apparatus. 8.1 Testing machine. 8.2 Troptometer. 9 Conditions of testing. . shear stress corresponding to the point reached during the torsion test at which plastic deformation occurs without any increase in the torque. 3.11.1.

torsion testing steps

Statics - Twisting Moments. Twisting moments, or torques, are forces acting through distances (“lever arms”) so as to pro- mote rotation. The simple example is that of using a wrench to tighten a nut on a bolt as shown in Figure 6: if the bolt, wrench, and force are all perpendicular to one another, the moment is just the force F times the length l of the wrench: \(T = F \cdot l\). Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability . The torsion test is used for the determination of the shear strength and shear modulus. The test is performed in round bars subjected to pure torsion and is relatively easy to perform. . 2.4.7 Combined Tension/Compression–Torsion Tube Test. In the tube test specimens are subjected to combined tension/compression and torsion.

FTIR, visual inspection, TGA, tensile test, VST, pressure test, DSC, and torsion test were performed to investigate the root cause for the failure. The findings demonstrate that the failed pipe had suffered serious torsion. The torsion led to the significant performance deterioration of reinforced fibers and liner pipe.

As a pipe stress analyst, it is critical to understand how wall thickness is determined. If the pipe wall is too thin, it will not matter how the pipe is supported; it will fail. Typically, the engineer designing the system also will determine the wall thickness; however, the wall thickness is also verified during the pipe stress analysis. In the bio-medical field, torsion testing is used to test materials that may experience a torsional load like a metallic bone screw, an intramedullary rod, or rubber tubing that may become twisted, or measure the shear strength of a bond between an implant and native tissue like bone. What shape is best for torsion?Circular shaft experiencing an axial torque. A solid, circular cross-sectioned shaft experiences an axial torque T, as shown above.. Angle of twist The hypothesis used in developing the stress and strain in the shaft is that all points on a cross-section of .

Bursting Tester agency

Cobb Absorbency Tester agency

Grêmio Corinthians live uitslagen (en gratis live stream intern.

test for torsion of tubing|metal torsion testing